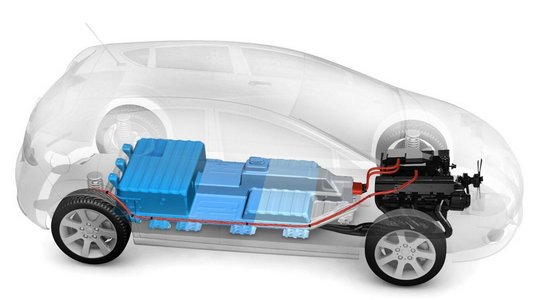

Lithium battery heater of green power car

1,Lithium battery industry background

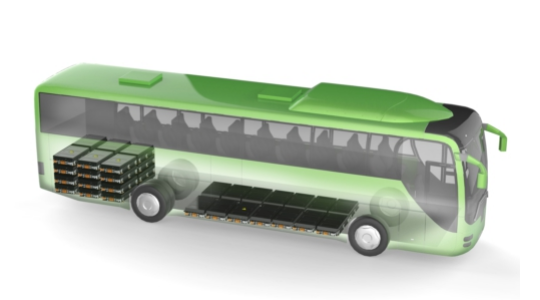

Lithium batteries are widely used in hydraulic power, fire power, wind power, solar power stations and other energy storage systems.The post telecommunications, electric bikes, electric motorcycles, electric vehicles, military equipment, aerospace and other fields also use that a lot.Lithium-ion batteries has been widely used with its unique performance advantages in portable electrical appliances such as portable computers, camcorders, mobile communication.

Large-capacity lithium-ion battery has been used in electric vehicles, and has become one of the main power supply of electric vehicles of the 21st century,and will be used in the satellite, aerospace and energy storage applications.

With the energy shortage and the world 's environmental pressure. Lithium is widely used in the electric car industry. in particular,the emergence of lithium iron phosphate materials come out, lithium battery industr.

2,Influence of Ambient Temperature on Lithium Battery Performance

In all environmental factors, the temperature has greatest impact on the battery charge and discharge performance . If the temperature goes down, the reaction rate of the electrode also decreases.

Assuming that the battery voltage remains constant and the discharge current decreases, the battery power output also decreases.If the temperature rises, lithium polymer battery output power will also rise.

Temperature also affects the electrolyte delivery rate, temperature rises too fast, transmission temperature decreases, transmission slows down, the battery charge and discharge performance will be affected.But the temperature is too high, more than 45 ℃, will destroy the battery chemical balance, leading to side effects.

Polymer lithium batteries such as nickel, nickel-metal hydride battery discharge efficiency will be significantly reduced (such as less than -15 ℃)at low temperature, and the lye reached the freezing point at -20 ℃,, the battery charging speed will be greatly reduced.It will increase the polymer lithium battery pack pressure and may make the safety valve open when charge at 0 ℃.

In order to effectively charge, the general ambient temperature range should be between 5-30 ℃.In general,charging efficiency will rise with the temperature rise, but when the temperature rises above 45 ℃, high temperature performance of rechargeable battery materials will be degraded, the battery cycle life will be greatly reduced.

Low ambient temperature greatly reduces the battery chemical reaction efficiency, increasing the battery internal resistance.Because of these two factors,the battery starting power decrease with the temperature going down.

On the other hand, according to the International Battery Institute statistics, the vehicle required starting power in the winter higher than in the summer 40% to 70%. Therefore, a full battery can only provide 40% of the starting power at -18 ° C, even if it is a new battery in good condition . So it is very important of the battery preheat in advance.

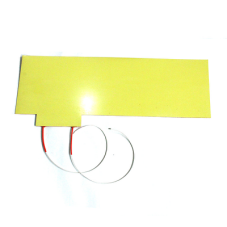

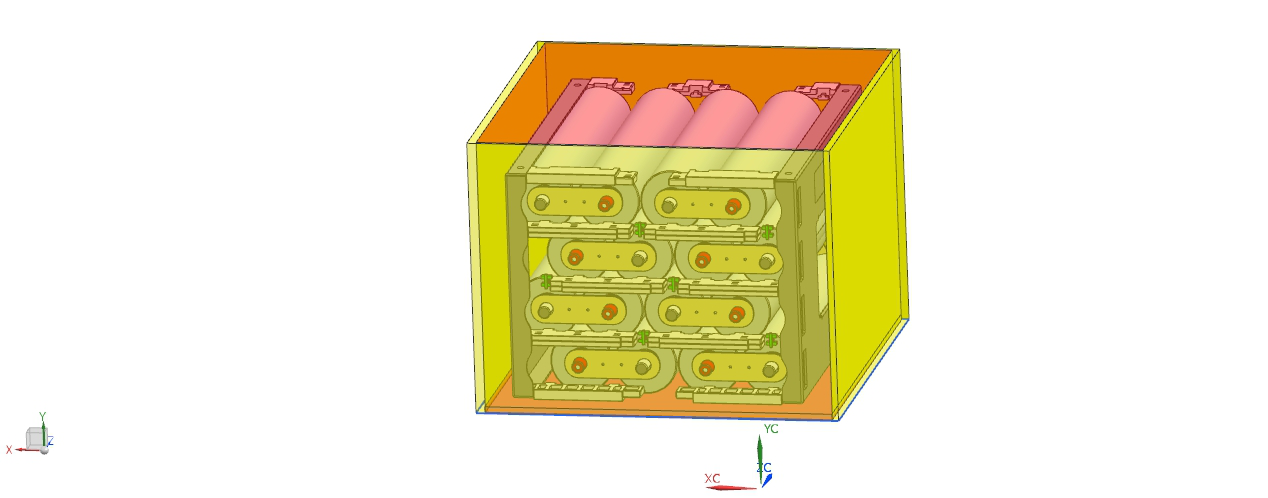

3,Silicone rubber lithium batteries heater

Lithium battery silicone rubber heater can play the full potential in the cold weather .It is a custom heating system made of nickel-chromium alloy wire and silicone rubber insulation layer.It is compact, soft and light, easy to install, suitable for most of the cars, trucks battery heating. At the same time optional insulation layer can reduce heat loss.Picture 3 and Picture 4 for the lithium battery with silicone heater, One side of the heater is epoxy board, the other side is of 3M adhesive paste,to make the installation of the product more convenient, in the meanwhile to increase the stability of the heating system.

According to the specific requirements of our customers, We custom lithium battery heating system. In order to avoid overheating, the power density of the battery heater is generally not more than 0.2 W / cm2.In addition, do not heat the battery incubator directly.