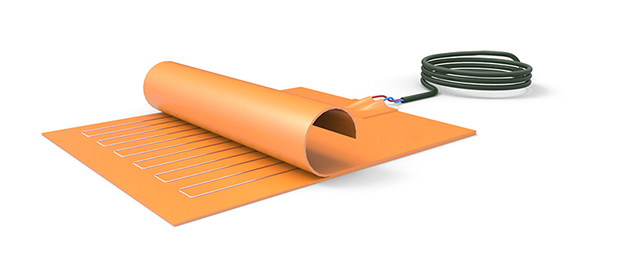

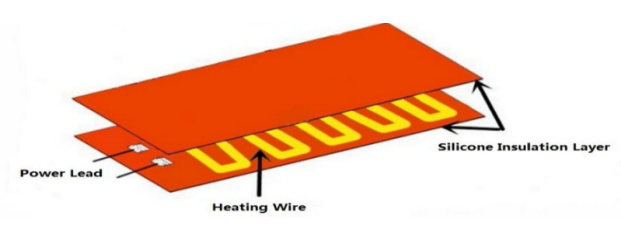

1.Composition of drum heater

The outer layer is composed of high temperature resistant silicone rubber and flame retardant glass fiber cloth. The internal heating elements are neatly arranged nickel-chromium resistance wires.

2.Product introduction

Silicone rubber drum heater has good waterproof performance. It can be used for wet, non-explosive gas place, industrial equipment or laboratory pipe, tank heating. It can be wound in the surface of heated parts directly. It is easy to install, safe and reliable.

Advantage:

It is easy to take liquid solid out when use drum heaters such as adhesive, grease, asphalt, paint, paraffin, oil and various resin raw materials. The viscosity decreases evenly via drums heat, it has no seasonal influence and can be used all year round.

3.Classification

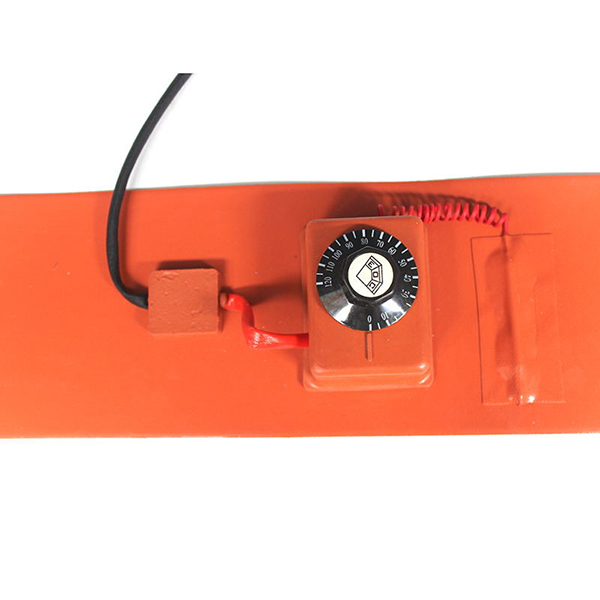

Temperature control on the heater

Temperature control outside the heater

Drum heater with steel springs

Drum heater with strips

Features:

The heater can install sensor on the surface and control the temperature directly by temperature controller(thermostat or digital temperature controller). Besides, the temperature control can be located on or off the heater. And the temperature controller range is 30-150℃. The temperature controller and silicone heater is an integral whole. Its weight is light and easy to install via metal buckle or strips.

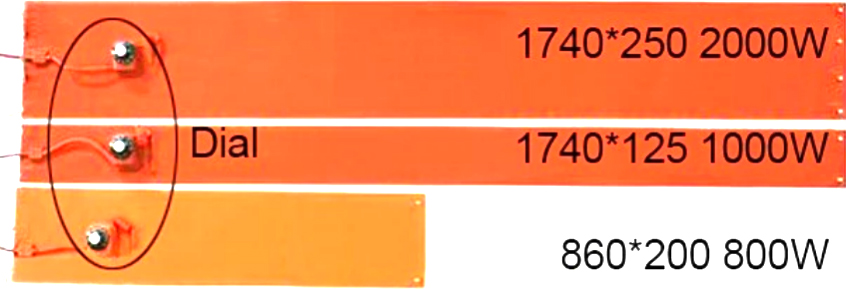

4.Standard size for drum heater

|

Drum capacity |

Size |

Voltage |

Power(W) |

Temperature control |

Weight |

|

200L |

250x1740mm |

110V-220V |

2000W |

30-15℃ knob temperature controller |

1.6kg |

|

200L |

125x1740mm |

1000W |

1.1kg |

||

|

20L |

200x860mm |

800W |

0.9kg |

||

|

20L |

120x860mm |

500W |

0.7kg |

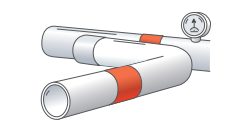

5.Installation steps of oil drum heater

(1) Fix the heater on the surface of the oil drum with the fixing device on the heater.

(2) Connect the heater to the power supply.

(3) Use the temperature controller on the heater to control the temperature of the heater.

For example: the temperature required by the oil drum is 40°C. Connect the heater to the power supply and rotate the button to 40°C. Then the heater will start to work.When the temperature in the oil drum is higher than 45°C, the heater will automatically disconnect and stop heating.When the temperature in the oil drum is below 35°C, the heater will start working again.This keeps the temperature in the barrel at 40°C.

Using tips:

Moistureproof specifications: flat plates, simple moistureproof, can not be used in water and frosty places for a longtime. Heaters temperature will change according to the different use environments, material and shape of the heated objects.

6. Maintenance of drum heater

A. The oil drum heater is a flexible heater, so the heater can be bent and saved. But the heating element in the heater is nickel chromium alloy resistance wire, its has a certain stiffness, therefore, the use and preservation of the heater, bending the diameter of the circle should be greater than 50cm.

B. Do not clean heater with corrosive liquid.

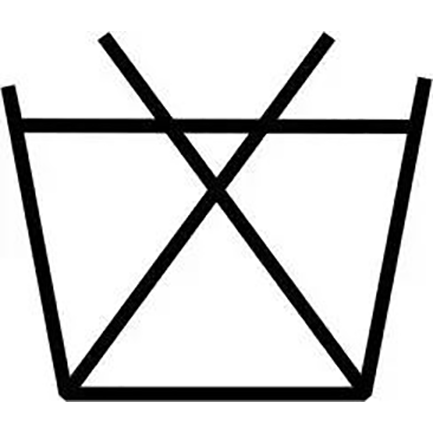

Note: do not put heater directly into water to clean.

C. The heater should not be scratched by sharp tools.

D. The heater cannot be heated in liquid.

7.Drum heater warranty

(1)The products produced by the company from the date of purchase, provide one year maintenance services.

(2)If you find any defects in the products during the warranty period, the company will be responsible for repair or replacement.

(3)If the product is damaged or malfunctions due to accident or improper use, or the product is modified or repaired without the written permission of the company, it is not covered by the warranty.